Your Location: Home >> Product Center >> High Reach Demolition >> High Reach Demolition Front

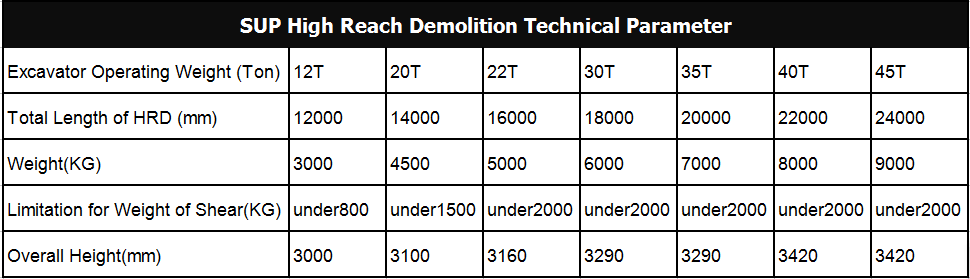

| Name: | High Reach Demolition Front |

|---|---|

| Applications: | Demolish high-rise buildings |

| Excavator Operating Weight: | From 12 ton or above |

| Brand Name: | SUP |

| Place of Origin: | Guangdong, China (Mainland) |

| Min.Order Quantity: | 1 set |

| Supply Ability: | 100 sets High reach demolition front per month |

| Delivery time: | within 30 days after received the deposit |

| Port: | Shenzhen,Guangzhou |

| OEM: | Acceptable |

PRODUCT DESCRIPTION

SUP High Reach Demolition Front, Help You Demolish High-rise Building Easier!

The traditional way of demolishing an old building was done by workers with hammers stand very closely to the building,this is really unsafe and inefficient.

High Reach Demolition Front is specially developed to solve such situation, which usually working with the hydraulic breaker or hydraulic shear at the top, reach the upper stories of buildings that are being demolished

and pull down the structure in a controlled direction.It can keep a safe distance between building and excavator when it’s working to protect the operator. It has largely replaced the wrecking ball as the primary tool for demolition.

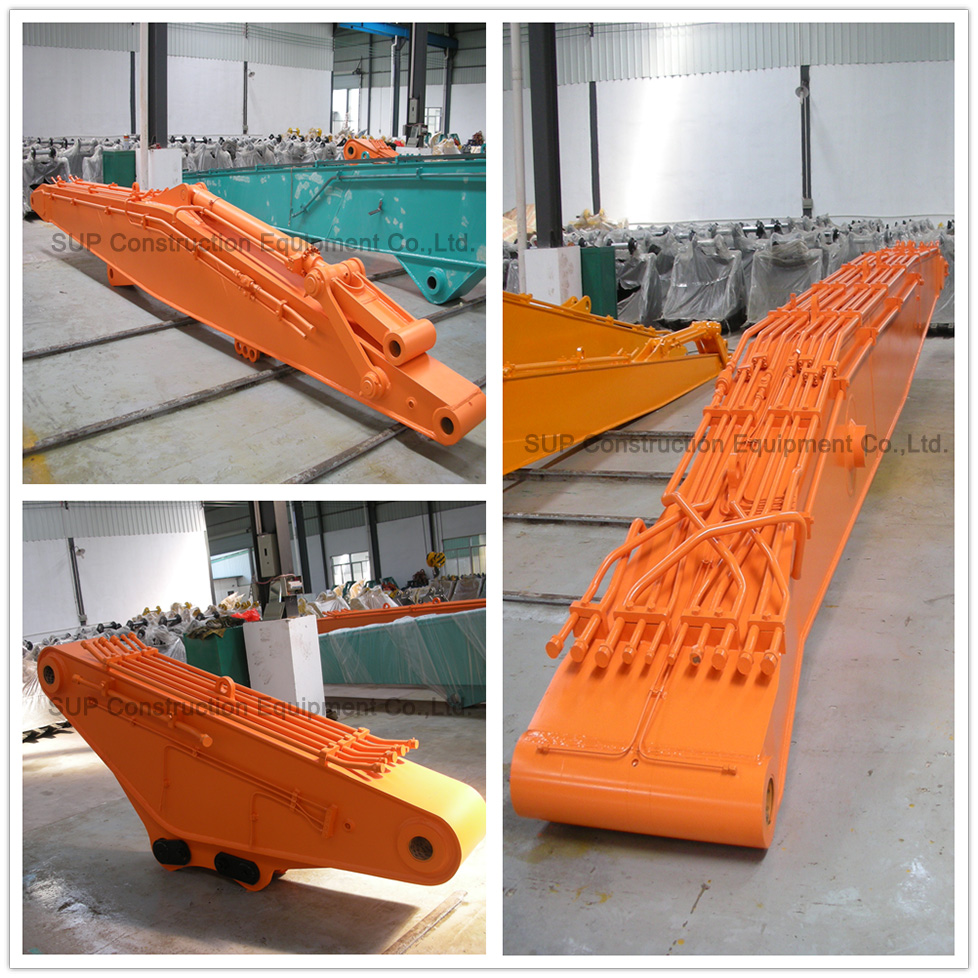

With strengthened long boom and arm, reinforced bucket linkage, the robust structure enable SUP High Reach Demolition Front to carry a competitive weight of work tool, provide you strong performance to tear down high-rise buildings or any other tough demolition projects!

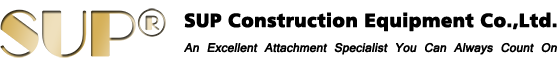

1)SUP adopt the advanced FEM (Finite Element Method) to analyze the stress distribution of products, through which we optimize

the structure the best,thickness of every steel plates are strictly selected, to make sure each our attachment is strong and reliable.

2)Material cutting is done by advance CNC flame plasma cutting machines.

3)Every steel plates are well beveled before welding, straight plates are beveled by large milling machine, circular or arc area are beveled by OTC

plasma cutting robot,this can improve the welding quality greatly.

4)Welding is done partly by skillful workers with at least 4 years experience, and partly by robotic welding machine, excellent welding quality is

guaranteed.

5)Ultrasonic flaw detector is used to detect products to ensure every welding beads are good enough.

6)Surface treatment for the products processed in Large sandblasting room,the treatment can release surface stress of product, remove dirt,

improve the adhesive force between the paint and products surface.

1)SUP optimize products’ structure the best through FEM analysis, we make our high reach demoliiton front stronger yet lighter,

which help you save fuels in every operation for it's lightened weight .

2)Reasonable ratios of boom,middle and arm, ensure you enjoy easy operation, safety and productivity.

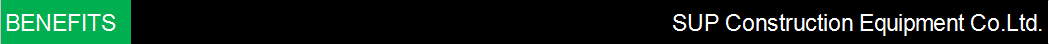

3)SUP select high quality cold-drown seamless tubes to make hydraulic lines, to prevent your hydraulic system been polluted.

4)Strong boom and arm enable it work long hours even in tough demolition projects.

SUP always listen to what our customer needs and provide reliable solutions.

Anytime, anywhere, SUP is Striving to provide the best products for you.

Important Notice:

1. The above parameters are for reference only, actual working range may be vary from different excavator models.

2. Specifications & dimensions are subjected to change without prior notice due to the sustained development and improvement

3. The color of actual products may differ from the pictures in this website

Each set of SUP High Reach Demolition Front standard package inculding below parts:

- 1 x long boom (with cold-drawn seamless steel tube made hydraulic lines)

- 1 x middle boom (with cold-drawn seamless steel tube made hydraulic lines)

- 1 x long arm/stick (with cold-drawn seamless steel tube made hydraulic lines)

- 1 set of bucket linkage

- 1 x bucket cylinder

- 11xpins

- 1 set of hyraulic hoses

Applicable Excavator Brands:

Applicable models:

Caterpillar Excavator:

CAT310,CAT312,CAT313,CAT315,CAT318,E200,CAT320,CAT323,CAT325,CAT326,CAT330,CAT336,CAT340,CAT345,CAT349,CAT350,CAT365,CAT374,CAT385,CAT390,CAT6018,CAT6020.

Hitachi Excavator:

EX100,EX120,EX200,EX210,EX220,EX230,EX300,EX350,EX360,EX400,EX450,EX550,EX600,EX650,EX670,EX850,EX870,EX1100,EX1200,EX1800;

ZX130,ZX150,ZX170,ZX200,ZH200,ZX210,ZX230,ZX240,ZX250,ZX260,ZX270,ZX300,ZX330,ZX350,ZX360,ZX400,ZX450,ZX470,ZX490,ZX670,ZX690,ZX700,ZX850,ZX870,ZX890,ZX1100,ZX1250.

KOBELCO Excavator:

SK100,SK120,SK130,SK140,SK200,SK210,SK220,SK230,SK250,SK260,SK270,SK280,SK300,SK330,SK350,SK380,SK400,SK450,SK460,SK480,SK495,SK850.

KOMATSU Excavator:

PC100,PC110,PC120,PC130,PC160,PC200,PC210,PC215,PC220,PC240,PC270,PC300,PC350,PC360,PC390,PC400,PC430,PC450,PC460,PC600,PC650,PC700,PC750,PC800,PC850,PC1000,PC1200,PC1250,HB205,HB215.

Volvo Excavator: EC120,EC140,EC170,EC200,EC210,EC220,EC240,EC250,EC290,EC300,EC350,EC360,EC380,EC460,EC480,EC700,EC750,EC950

CASE Excavator: CX130,CX135,CX160,CX180,CX210,CX220,CX225,CX240,CX260,CX290,CX360,CX300,CX350,CX380,CX470,CX490,CX500,CX700,CX800.

Sumitomo Excavator: SH100,SH120,SH130,SH180,SH200,SH210,SH240,SH260,SH280,S280,S340,SH300,SH350,SH360,SH380,SH400,SH450,SH480,SH700.

Hyundai Excavator:

R110,R130,R150,R200,R210,R215,R220,R225LC,R230,R275,R290,R300LC,R305LC,R330LC,R350,R360LC,R400,R450LC,R375,R385,R485,R520,R800,R850.

DOOSAN/DAEWOO Excavator:

DH200,DH220,DH280,DH290,DH300,DH340,DH360,DH420,DH470,DH500,DH550,DH600,DX130,DX150,DX200,DX215,DX220,DX225,DX230,DX260,DX300,DX340,DX380,DX420,DX500,DX520,DX800

Liebherr Excavator:R313,R317,R900,R906,R916,R924,R926,R942,R954,R964,R974,R984,R9250,R9350,R994,R995,R996,R9800.

CATO Excavator:HD250,HD400,HD450,HD550,HD700,HD800,HD820,HD900 HD1230,HD1250,HD1430,HD1880.

Choose SUP, gain superior quality attachments and long-term partner.